Email: info@singermachinery.com | Telephone: (+98 21) 77358514, 77349516

In the epidemic context, the demand for blood collection tubes is enormous, and the global average annual demand is about 20 billion. A growth rate of 10% is far ahead of overall medicaldevice growth.

However, the domestic market of high-end blood collection tube systems is still monopolized by imported products. Under fierce competition and huge demand, the blood collection tube has stricter requirements on its injection molding techniques.

Requirements:

۱٫ Medical Grade Cleanliness:

Serum samples cannot be contaminated, and the equipment must achieve medically clean.

۲٫ High Precision

It ensures that the vacuum sealing of the tube body and the stability of the equipment also affects the original properties of the blood sample.

۳٫ High Production Quality Requirements

The blood collection tube needs to withstand the relative centrifugal force of about 3000g of the horizontal centrifuge.

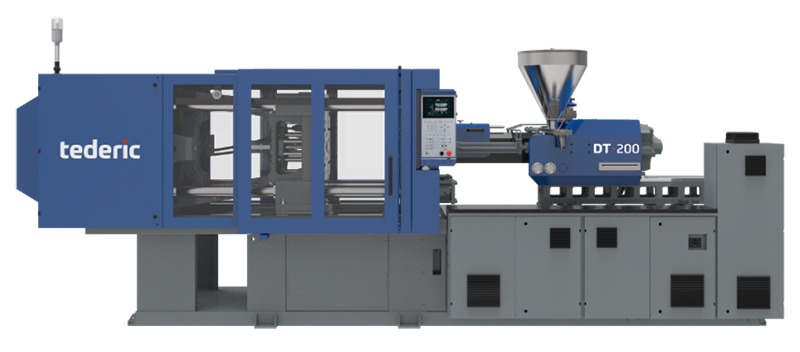

Take a look at Tederic’s blood collection tube solution

Solution Highlights:

There will be more medical solutions, so please follow us!