Email: info@singermachinery.com | Telephone: (+98 21) 77358514, 77349516

(hereinafter referred to as: Chenfeng) is a national high-tech enterprise (stock code: 603685) that integrates the research and development, design, production, and sales of LED, lamp head, and lighting accessories.

At present, Chenfeng is the No.1 in sales of radiators in China and the No.1 in sales of lamp heads in the world. It has been regarded as the “world’s largest LED supplier” by leading lighting companies such as Philips, Osram, and Dixon. Its products are exported to over 20 countries and regions, including Germany, France, the United States, and India.

Since 2017, Tederic has cooperated with Chenfeng to develop and produce core products such as radiators and PC covers, helping Chenfeng improve its core product competitiveness while achieving lean operational efficiency management.

Mr. Ling, the person in charge of production in Chenfeng, said that Chenfeng is a fully automated injection workshop, which poses a considerable challenge to the degree of adaptation of injection machines and automated assembly lines, injection precision, and product accuracy, stability, and mold fit.

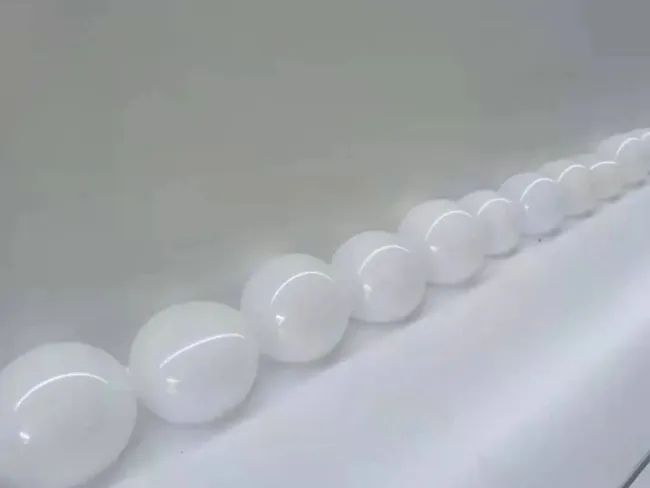

While pursuing an automated and intelligent production mode, Chenfeng attaches great importance to product quality and control. Production is strictly by IEC and GB standards and is guaranteed to pass the ISO9001 quality system certification. In the case of bulbs, they need to meet high light transmission, high diffusion, no glare, and no light shadow at the same time.

At present, whether it is Chenfeng’s domestic or foreign factories, as soon as you walk into the workshop, you will see hundreds of Tederic electric injection molding machines running steadily around the clock.

▲Tederic electric injection molding machines in Chenfeng factory

Creating a new benchmark for products together

According to the customer’s demand for the product, Tederic and Chenfeng have cooperated in depth from the research and development link to the practical application, through the continuous optimization of the solution, and finally realized the integrated energy-saving production solution.

Through the BlowSure™ ( Tederic integrated injection and blowing technology), the investment from additional equipment, workforce, and materials is greatly reduced. Regarding product yield, the Tederic electric injection molding machine with full servo motor precision control has a screw concentricity of 0.03mm, perfectly coping with defects such as yellowing, black spots, bubbles, and poor light transmission. With a yield rate of 99%!

In addition, the Tederic Electric injection molding machine’s advanced energy recovery system also helps Chenfeng move towards high quality and green sustainable development, saving 32.1% of energy compared to the peer motor and 54.6% compared to the hydraulic machine!

▲Chenfeng Production Base Injection Moulding Workshop

Ling is happy to say, “After using Tederic electric injection molding machine for our main product, the bulb, its BlowSure™ allows the product to be formed in one piece and to produce thinner wall thickness products, saving production materials. Tederic’s electric injection molding machine solution has helped us save millions of dollars in energy consumption and raw materials.”

▲Chenfeng introduces Tederic electric technology to its core products.

Helping customers improve their “soft power” to achieve high-quality development.

In addition to equipment, Tederic also provides customers with an intelligent factory management system, which greatly reduces the difficulty of Chenfeng’s fully automated production, helping to increase Chenfeng’s overall production efficiency by more than 20% and achieving double improvement in production efficiency and product efficiency.

The 22-acre production base has delivered a beautiful answer with an annual production capacity of up to 3.5 billion LED high-transmission lampshades, radiators, and other system accessories. This has also become a vivid practice of Tederic tech’s creative power to help the enterprise economy and a vivid sample of the digital enterprise reform.

Mr. Ling said: “The injection molding machine and the automation equipment are like the relationship between the “heart” and the “hands and feet,” they form a whole and cooperate to produce better products. These hundreds of Tederic Electric injection molding machines can run 24 hours a day, are very stable, and work very well with the automation line!”

▲Injection molding workshop at Chenfeng production base

Customer focus and creating greater value for our customers is Tederic’s philosophy in serving every one of our customers. As a leader in intelligent injection molding, Tederic will continue to develop and innovate and is committed to providing the best one-stop injection molding solution and customer experience for our global customers.